Updated February 3, 2021

Lantos Technologies, Derry, NH, is seeking to change the way audiologists and hearing aid specialists see and model the ear canal during the hearing aid impression-taking process for both ITE custom-fit and RIC hearing aid earmolds. The company has relaunched its proven 3D ear scanning technology with a new corporate and investment team headed up by CEO Paul Harkness, who has served for over 25 years in various executive posts within hearing aid manufacturer and distribution companies, including as senior vice president of Amplifon’s Elite Hearing Network.

Harkness cites the disruptive elements affecting hearing healthcare, including the rising of managed care and third-party payers, Big Box retailers, and the upcoming new class of over-the-counter (OTC) hearing aids. These forces will continue to drive hearing aid dispensing practices toward more efficient best practices and customized patient-centered care (PCC) for individuals with hearing loss. It will also necessitate differentiation of professional dispensing offices from OTC and self-fit online devices.

“Our technology enables practitioners to truly “own the ear” and become the full-service ear resource for people everywhere,” he says. “So, I would simply say this to practitioners: Let’s make it clear to patients everywhere who their go-to ear expert is.”

See the interview with Harkness below:

A Better, More Practical System for “Customized Sound” and Individualization

With the relaunch of the company, the Lantos 3D Ear Scanning System equipment will now be charging fees on a per-patient basis, making it easier for all practices to obtain and adopt the technology, according to Harkness. Training and support are also included as part of the system.

Harkness says the Lantos 3D Ear Scanning System will also allow dispensing professionals to use more custom-fit products for all hearing aid fittings, including the most-popular RIC and RITE style hearing which account for about 4-in-5 (79%) of all US hearing aids dispensed in 2020. The choice of earmold/eartip has large implications, both in terms of how much direct sound is transmitted and how much low-frequency sound escapes through the ear tip/earmold, and Harkness predicts that Lantos technology will revive the important benefits in custom earmolds, resulting in enhanced sound quality, retention, better feedback and occlusion control, and comfort for the wearer—resulting in greater patient satisfaction and loyalty.

“Patients prefer custom fit solutions and, we believe, delivering such an experience will improve satisfaction and retention,” says Harkness. “Our focus will be on making our 3D ear scanning system easy and inexpensive to acquire for the practice. We look forward to helping practitioners everywhere incorporate 3D ear scanning as the next best practice standard of care, so as to build their business around this differentiator.”

“Patients deserve optimal care when they visit a hearing care professional,” says Lantos Founding Strategy Advisor Susan Whichard, whose career has included owning and running a successful private practice as well as several executive positions within the hearing industry. “Today that care should include a Lantos 3D ear scan that can be used to quickly order a custom hearing device, a custom RIC tip or earmold, custom hearing protection, or a consumer audio mold.”

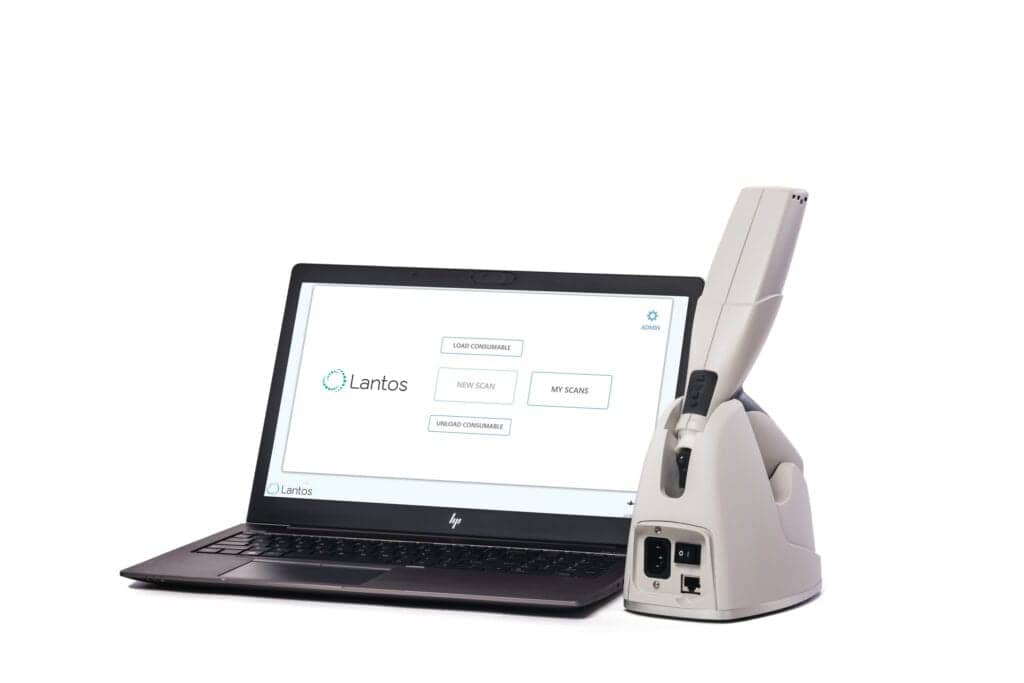

The Lantos System

Although the benefits of a custom earmold are evident for a wide range of hearing aid fittings, impression-taking remains something of an art that uses many different materials and techniques, and some clinicians have proven to be better artists than others—as noted in numerous Hearing Review articles on this subject. The various methods and unnecessary time lost in preparing earmold materials and cleaning can result in longer and/or multiple office visits, and, in worst-case scenarios, discomfort for patients, frustration for dispensing professionals, and extra costs for hearing aid manufacturers (and consumers) in the form of hearing aid returns.

Lantos Technologies’ 3D scanning system, which originated about 10 years ago from the Massachusetts Institute of Technology (MIT), eliminates the need for taking physical ear impressions with standard impression material. Utilizing a handheld video otoscope/scanner that maps the interior of a liquid-filled conforming membrane (CM) inside the ear canal, the system is designed to take accurate 3D images safely beyond the second bend.

As shown in an online video, the Lantos Scanner is a small handheld device composed of a fiberscope enclosed in a conforming membrane, which is then inserted into the patient’s ear canal. The conforming membrane is subsequently filled with liquid, causing the membrane to expand and conform to the shape of the ear canal. Next, the fiberscope retracts and generates a dynamic 3-D image of the ear canal in real time. The entire scan takes less than 60 seconds, and the scanning data can be sent online to the hearing aid manufacturer or earmold fabricator immediately anywhere in the world. Advantages include a no-mess highly detailed 3D representation of the ear for better, faster hearing aid fittings, and more efficient communication with the hearing aid manufacturer.

More Details…

For more information, visit https://www.lantostechnologies.com or contact Harkness at [email protected].

Hearing Review thanks Susan Whichard for her assistance on this article.